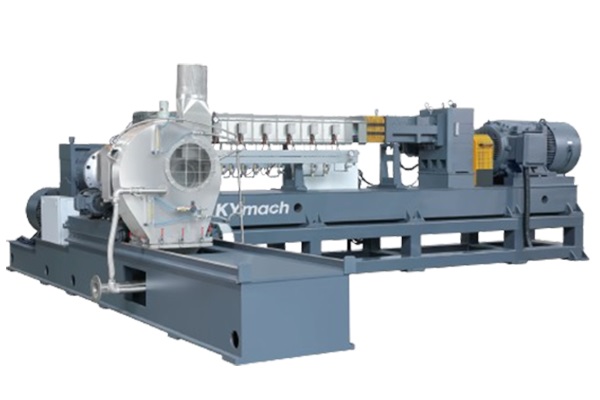

In the vast realm of plastic processing and material molding, the twin-screw extruder pelletizer is akin to a powerful technological storm, leading the industry towards more efficient and refined manufacturing frontiers with its unique dual-drive parallel design. This is not merely a revolution of a machine but a profound subversion and reshaping of traditional plastic processing technology.

The twin-screw extruder pelletizer, as the name suggests, has its core in two co-rotating screws that work together to form a precise and efficient material transport and mixing system. This design completely transforms the limitations of traditional single-screw extruders in terms of material transport, melting, mixing, and exhaust. The coordinated work of the two screws, akin to two perfect dancers on a rotating stage, weaves a magnificent picture of uniform material mixing and efficient transport. The result is a significant increase in production efficiency, more stable and reliable product quality, meeting the urgent needs of modern industry for high-quality plastic products.

The innovation of the twin-screw extruder pelletizer goes beyond this. With the integration of intelligent and automated technology, modern twin-screw extruder pelletizers can achieve remote monitoring, precise control, and fault warning functions. This not only greatly reduces labor costs but also improves production safety, providing businesses with unprecedented flexibility and competitiveness. Additionally, optimized designs for specific materials and applications, such as high-filling, high-viscosity material processing, showcase the extruder pelletizer's exceptional ability to solve complex processing problems.

In today's globally acknowledged need for environmental protection, the twin-screw extruder pelletizer actively responds to the call for green manufacturing. By optimizing energy consumption structures, improving energy utilization efficiency, and adopting environmentally friendly materials, the extruder pelletizer plays a crucial role in reducing carbon emissions in the production process and achieving resource recycling. It is not only an effective assistant in plastic product manufacturing but also a significant force in driving the industry towards green and low-carbon transformation.

With its innovative dual-drive parallel design, efficient and stable production performance, and green manufacturing concept, the twin-screw extruder pelletizer is gradually becoming a star product in the plastic processing industry. It is not only a symbol of technological progress but also a weather vane for the future development of the plastic manufacturing industry. In this era full of challenges and opportunities, the extruder pelletizer will continue to lead us in exploring broader chapters in the world of plastic manufacturing with its unique charm.

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China