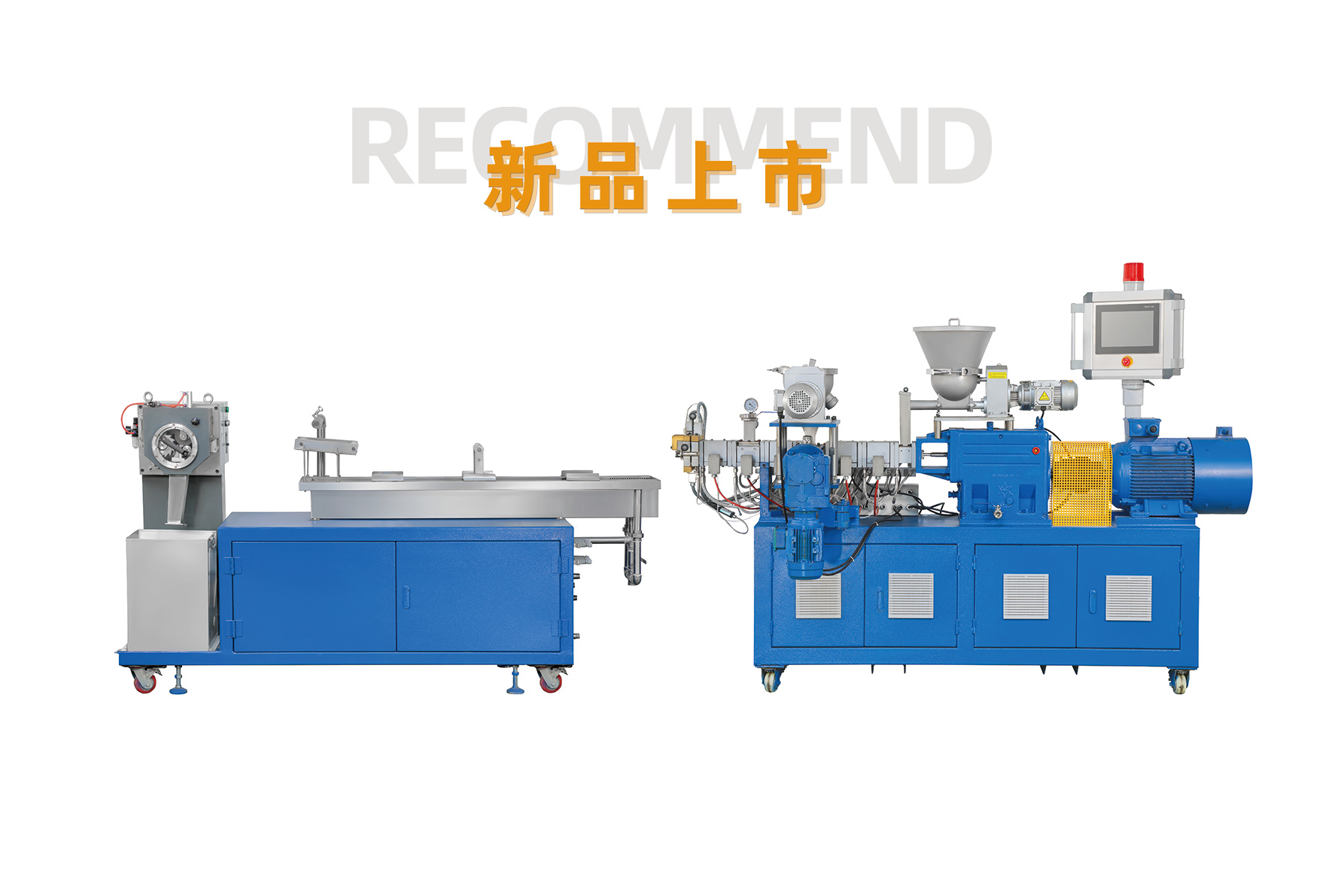

HK MT Series Co-rotating Twin Screw Extruder

KY-lab Experimental Twin Screw Extruder

As society progresses, plastic products gradually become indispensable in people's daily lives. The twin screw extruder, being a commonly used plastic processing machine, has also seen an increasingly broad range of applications.

Basic Structure and Principle of the Twin Screw Extruder

The twin screw extruder consists of a pair of counter-rotating screws and heating rings. The threads on the screws mix, plasticize, and extrude the plastic under the effect of heat, pressure, and shear. The principle is to fill preheated plastic into the sealed chamber of the screws, and through the rotation and pressure of the screws, extrude the plastic from the extrusion outlet.

The twin screw extruder has the following advantages:

Better plasticizing effect, producing more uniform extruded products.

Can accommodate a wider variety of plastic materials, thus having a broader scope of application.

Higher working efficiency and stronger production capacity.

The twin screw extrusion granulator is widely used in the plastics, rubber, cosmetics, pharmaceutical, and food industries. Among these, plastic processing is the main application area for the twin screw extruder. In plastic processing, the twin screw extruder can process and form various plastic products, such as plastic films, plastic pellets, plastic pipes, and plastic sheets.

In summary, the application of twin screw extruders in plastic processing has been widely recognized. In future development, we anticipate that twin screw extruders will play an even more important role in various fields.

Related News

News

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

English

English  日本語

日本語  한국어

한국어  français

français  Español

Español  русский

русский  português

português  العربية

العربية  中文

中文