Degradable plastics refer to plastics that can be degraded under natural conditions (such as soil/sand, etc.) or specific conditions (such as composting, anaerobic digestion, water-based culture media) by microorganisms present in nature, and ultimately completely degraded into carbon dioxide (CO2), methane (CH4), water (H2O), mineralized inorganic salts, and new biomass (such as microbial dead bodies, etc.).

Depending on the source of raw materials, degradable plastics can be divided into two categories: biodegradable plastics (such as PLA and PHA) and petrochemical degradable plastics (such as PBAT, PBS, PPC, PGA).

For film bag: PBAT+PLA+starch, PBAT+calcium carbonate

For tableware: PLA+PBAT+talc powder, PLA+plant fiber+silica fume, PBS+PLA+calcium carbonate, PBS+bamboo powder+starch, PBS+PLA+straw,straw powder+PLA+talc powder, PLA+PBAT+PHA+talc powder, and etc.

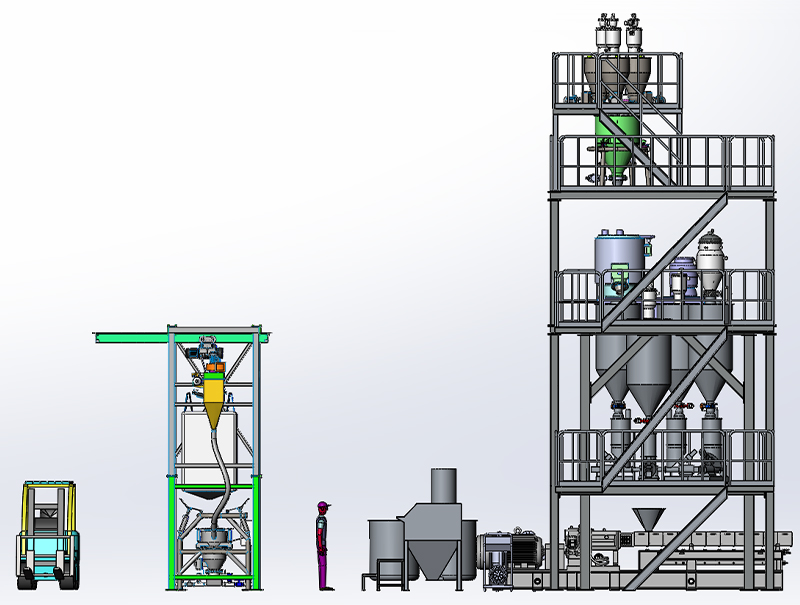

Feeding system

1. Starch, liquid, and additives are transported to the batching system through vacuum loading, and then pre treated by a mixer before being transported to the saving silo.

2. The remaining raw materials are transported to various saving silos through vacuum loading.

3. Based on the settings, the above materials enters the loss-in-weight feeder from the solid. It then goes into the extruder after being measured.

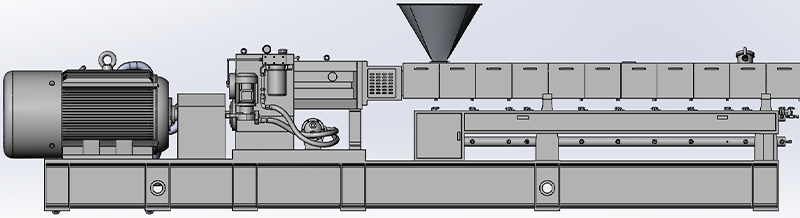

Twin screw extruder

The raw materials are plasticized, mixed, air discharged or vacuumed, and extruded into dozens of strips through twin screw extruder.

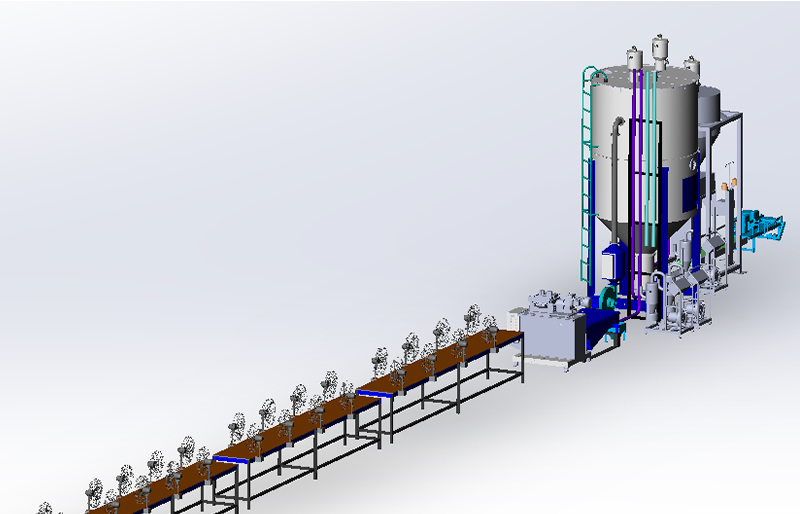

Pelletizing and packaging

Strips are cooled by stainless steel air-cooled conveyor belt and then cut into pellets by the pelletizer. The screened pellets enter the finished product silo for drying and homogenization, then vacuum sealed and packaged.

Machine Model | Motor Power | Screw Speed | Capacity |

HK-73 | 160kw | 40-400r/min | ~300kg/h |

HK-73MT | 200kw | 40-400r/min | ~400kg/h |

SK-73 | 250kw | 40-400r/min | ~450kg/h |

A certain high-tech company

We have provided HK-73 and SK-73 twin screw extruder production lines, with an annual output of over 10000 tons of PBAT modified materials.

A biotechnology company in Shandong

We have provided 8* HK-73 and 2* HK-73 MT series twin screw extruder production lines.

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China