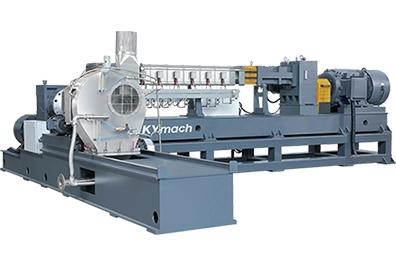

HKY 73-180 low smoke halogen-free (HFFR) or halogen-free flame retardant cable material: the upper stage is HK 73 twin screw extruder, KY production of high torque twin screw transmission box, the highest speed of screw 400 rpm, motor power 160-200 kW, configuration of side forced feeder for powder side forced feeding, improve the feeding quantity. The lower stage is SE 180 single screw extruder, with a diameter of 180 mm, a maximum speed of 60-90 rpm and a power of 45-55 kW.

The head of HKY extruder pelletizer is equipped with eccentric air-cooled die surface hot granulation. After the granulation is completed, the conveyor fan is used to convey the granulation to the cyclone separator for cooling, and then the granulation is further sifted and cooled through a vibrating screen and then conveyed to the finished product silo for storage. HKY model produces low smoke halogen-free (HFFR) or halogen-free flame retardant cable materials with a production range of 600-1000kg/h.

Customers can also choose SKY China twin screw extruder with higher output according to production requirements, such as SKY 73-200: SK 73 twin-screw extruder with imported high-torque transmission box from Germany. The highest speed of the screw is 400 rpm, the power of the motor is 200-250 kW, the lower level is SE 200 single-screw extruder, the diameter of the screw is 200 mm, the highest speed of the screw is 60 rpm, and the power of the motor is 75 kW. SKY model produces low smoke halogen-free (HFFR) or halogen-free flame-retardant cable materials in the product range of 700-1500kg/h.

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China