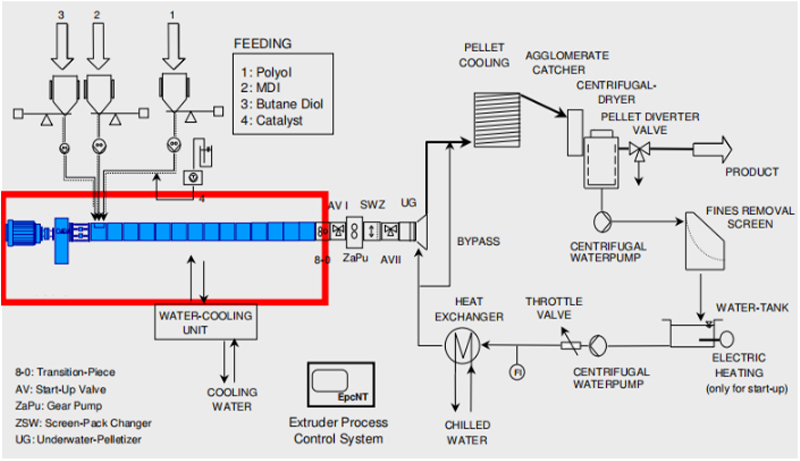

It not only has high elasticity, aging resistance, and oil resistance of traditional cross-linked vulcanized rubber, but also is convenient and can be easily processed like regular plastic. Due to different processes, it is mainly divided into chemical synthesis type and rubber plastic compounding type. The former appears separately in the form of polymers and can be divided into main chain copolymerization, grafting copolymerization, and ion polymerization. The latter is mainly a compound of rubber and resin, including dynamic vulcanized rubber (TPE-TPV) and interpenetrating polymer network (TPE-IPN) that appear through cross-linking vulcanization. The production process involves measuring, compounding, melting, extruding, and pelletizing the main materials and additives through twin screw extruder.

Polymerization reaction type elastomer TPU, rubber plastic compound type elastomer TPE, dynamic vulcanization type elastomer TPV

Upstream and downstream supporting equipment

The upstream adopts the “five component liquid quantitative mixing unit”, which contains one polyol (POLYOL1/B) tank, one diphenylmethane diisocyanate (MDI/A1) tank, one hexamethylene diisocyanate (HDI/A2) tank, one chain extender (BDO/C1) tank, and one additive (C2) tank. The “quantitative mixing unit” which uses servo speed controller combined with respective flow meters to control the output flow rate of the metering pump, specifically designed for TPU elastomers.

Downstream adopts the underwater pelletizing unit, including screen changer, start-up valve, underwater pelletizer, centrifugal dewatering and drying, and etc., to complete TPU pelletizing.

Equipment parameters:

SK73 twin screw extruder

-Set the temperature to 140-250 ℃;

-Die head pressure 4-7Mpa;

-Screw speed: 200-300rpm

Zhejiang Rock New Materials has an annual production of 3000 tons of TPU.

We have provided SK-73 twin screw extruder, equipped with the "five component liquid quantitative mixing unit" and an underwater pelletizing unit, achieving a production capacity of 400-500kg/h.

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China