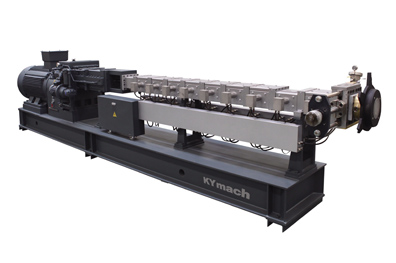

Twin-Screw Extruder is a highly efficient and precise plastic processing equipment, widely used in industries such as plastics, rubber, and chemical fibers. Compared to traditional single-screw extruders, Twin-Screw Extruder has more advantages. Below, we will discuss the advantages and application areas of Twin-Screw Extruder from multiple aspects.

High output: China Twin-Screw Extruder has two screws, rotating in sync, can better mix and convey materials, making the material more uniform during the extrusion process, improving production efficiency, and achieving high output.

Excellent plasticizing performance: The screw design allows materials to be better plasticized during the extrusion process, reducing material residue and waste, and improving product quality and stability.

Wide adaptability: It can process a variety of raw materials such as plastics, rubber, and chemical fibers, and can easily adjust the screw speed and temperature to meet the production needs of different products.

Easy maintenance and operation: The relatively simple structure makes operation and maintenance convenient, reducing the production and maintenance costs for companies.

Plastic processing: It is widely used in the field of plastic processing, where it can be used to produce plastic pipes, plastic films, plastic profiles, plastic sheets, and other products.

Rubber processing: It can also be used in the rubber processing industry to produce rubber pipes, rubber sheets, rubber profiles, and other products.

Chemical fiber processing: It has a wide range of applications in the chemical fiber processing industry, where it can be used to produce chemical fibers, chemical fiber fabrics, and other products.

Other areas: In addition to the above-mentioned fields, extruders can also be applied in construction materials, packaging, automotive components, and other fields.

The small plastic extruder is more cost-effective, easy to operate, takes up less space and consumes less material. It is mainly used in R&D institutions and laboratories. Compared with the floor-standing open mill series, mini extrusion machine can mix smaller batches of materials. For example, the 12 mm co rotating extruder is very suitable for processing small batches of polymers.

In conclusion, Twin-Screw Extruder, as a highly efficient and precise plastic processing equipment, has a wide range of advantages and application areas. With continuous technological advancements and the expansion of application areas, the future development prospects of extruders will be even broader.

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China