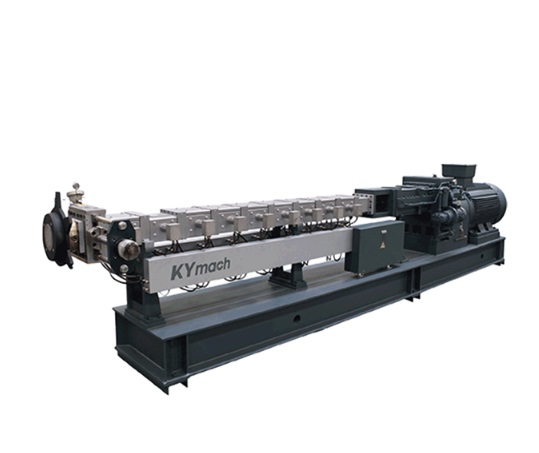

In the field of modern polymer material processing, the parallel co-rotating twin-screw granulator has become an indispensable processing equipment in many industries due to its excellent performance and wide range of applications.

The parallel co-rotating twin-screw granulator stands out with its unique twin-screw design. The two screws, arranged in parallel, rotate within the screw grooves, engaging with each other to efficiently melt, mix, and extrude the plastic raw materials. This design not only improves the mixing effect of the materials but also ensures the high quality and consistency of the granular products. Additionally, the gap between the twin screws is adjustable and can be optimized based on different material characteristics, further enhancing the equipment's adaptability and flexibility.

Working Principle: Precision Coordination, Efficient Production

Working Principle: Precision Coordination, Efficient ProductionDuring operation, the parallel co-rotating twin-screw granulator first feeds plastic raw materials into the machine through the hopper. As the twin screws rotate and compress, the material gradually becomes denser and, through the shearing, stirring, and conveying actions of the screws, melts and mixes. Meanwhile, the machine's heating device heats the raw materials to their melting point, ensuring the material can smoothly melt and distribute evenly throughout the screw grooves. Ultimately, through extrusion and cutting by the die head, the plastic raw materials are processed into granular products.

The parallel co-rotating twin-screw granulator, with its efficient and precise production capabilities, is widely used in multiple industries such as pharmaceuticals, food, and chemicals. In the pharmaceutical field, this equipment can be used to prepare tablets, granules, and capsules, ensuring the quality and safety of medicines; in the food industry, it can be used to process various food granules, enhancing the product's taste and nutritional value. Moreover, in the chemical sector, the twin-screw granulator also plays an important role, such as in the preparation of granular products of polymers like polypropylene and polyethylene.

In summary, the parallel co-rotating twin-screw granulator, with its efficient, precise, and flexible design, has become an essential device in the polymer material processing field. It not only improves production efficiency but also ensures the high quality and consistency of products.

News

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

English

English  日本語

日本語  한국어

한국어  français

français  Español

Español  русский

русский  português

português  العربية

العربية  中文

中文