Nanjing KY provides more material selections for the process parts of the HK Series Co-rotating Twin Screw Extruder. Besides standard nitriding steel and tool steel, the HIP materials made in China also provide higher wear resistance for co-rotating extruder machines. Different corrosive powder metallurgy materials are also applied to screw element and cylinder bushing manufacture, and their properties are very close to the same.

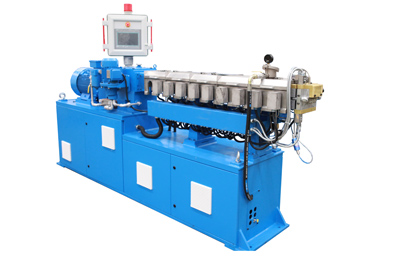

HK Extruder for Small Batch Production

HK Extruder for Small Batch Production

HK36 and HK53 are very competitive equipment models for small batch production scale, especially for the Color Masterbatch industry.

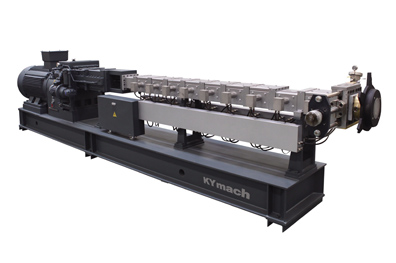

HK Extruder for Mass Production

HK Extruder for Mass Production

In the field of engineering plastics and high filling, mass production and stability have always been the most concerned problem for users.

HK Large Extruder Production System

HK Large Extruder Production System

KY also offers a larger-scale HK extruder, with the commonly used screw diameters ranging from 110 mm to 165 mm (HK110-165) available for user selection.

The process components of KY's HK co-rotating twin-screw extruder series, such as the screw and cylinder, can be interchanged with AK or SK specifications, and the geometric design of this extrusion screw for sale is completely consistent. This also means that customers of Nanjing KY AK or SK can seamlessly transfer the original products to newly purchased HK equipment, to achieve higher output or better return on investment.

HK Series Twin-screw extruder is a medium-high torque and high-speed co-rotating extruder launched by Nanjing KY in recent years to meet the new needs of customers. It has gained a huge market share and currently produces more than 120 extruders annually.

HK transmission system including large extruder production system based on Nanjing KY independently developed high-torque gearbox adopts the leading transmission technology in the industry, strengthens the output system of the gearbox with enhanced structure, achieves the ideal result of pure torque output with parallel biaxial output, and greatly improves the safety of gearbox. The transmission parts of our co-rotating twin screw extruder machine can be manufactured by German or British torque limiter so that gearboxes and process parts can be safely protected when the torque exceeds the standard. As a mature extruder machine manufacturer, Keya would love to be your premier twin-screw extruder partner.

Polymer Blending and Compounding: Our lab co-rotating twin screw extruders are ideal for polymer blending and compounding applications. Whether you are developing new polymer blends or enhancing existing formulations, our extruders provide precise control over temperature, shear, and mixing, ensuring consistent and high-quality results every time.

Material Development and Testing: In the field of material science, our extruders are indispensable tools for developing and testing new materials. From nanocomposites to biodegradable plastics, our equipment allows researchers to experiment with various additives and fillers, optimizing material properties for specific applications.

Pharmaceutical and Biomedical Research: Our lab co-rotating extruders are also widely used in pharmaceutical and biomedical research. They enable the production of drug delivery systems, such as controlled-release tablets and implants, by precisely mixing active pharmaceutical ingredients with excipients. This ensures uniform distribution and optimal performance of the final product.

Food and Nutraceuticals: In the food industry, our twin screw extruders are used for developing and testing new food products and nutraceuticals. They allow for the precise control of ingredient mixing, cooking, and shaping processes, making them perfect for creating innovative and high-quality food products.

Chemical and Catalytic Processes: Our extruders are also employed in chemical and catalytic process research. They facilitate the continuous mixing and reaction of chemical compounds, enabling the development of new catalysts and chemical processes with improved efficiency and selectivity.

As the names themselves suggest, while the screws of the co-rotating twin screw extruders will rotate in the same direction, the screws of the counter rotating screw extruder machine will rotate in opposite directions. As for the co-rotating extruder, there are two possible ways to rotate, either clockwise or counterclockwise. In practice, the more common one is clockwise rotation and the screw thread should be right-handed. And regarding the counter-rotating twin-screw machines, they normally use inward rotation and outward rotation.

| HK Series Co-rotating Twin Screw Extruder Model | Production Capacity kg/hr (Reference Value) | |||||||

| Material Process Category | Typical Material | HK26 | HK36 | HK53 | HK63 | HK73 | HK96 | HK136 |

| Filling modification | PE, PP, EVA, etc. + calcium carbonate, talcum powder, titanium dioxide | 5~10 | 40 ~ 80 | 130 ~ 260 | 260 ~ 460 | 500 ~ 700 | 1000 ~ 1300 | 1500 ~ 2300 |

| ABS, PC, PS, etc. + aluminum hydroxide, magnesium hydroxide, antimony oxide | ||||||||

| PP, PA, ABS, etc. + iron powder, magnetic powder, ceramic powder | 10 ~ 20 | 80 ~ 120 | 160 ~ 260 | 330 ~ 460 | 600 ~ 800 | 1200 ~ 1600 | 1500 ~ 2600 | |

| Blending modification | PP, PE, PS + SBS; PP, PA + EPDM; PP + NBE; EVA + silicone rubber etc | 5~ 10 | 50 ~ 100 | 130 ~ 210 | 230 ~ 390 | 450 ~ 650 | 900 ~ 1400 | 1400 ~ 2600 |

| PE, PA, PC, CPE + ABS; ABS + TPU; PBT + PET; PP + PE etc | 5~ 10 | 40 ~ 80 | 100 ~ 210 | 230 ~ 330 | 400 ~ 500 | 850 ~ 1300 | 1000 ~ 2600 | |

| Color masterbatch | PE, PP, ABS, EVA, PS, etc. + pigments and other additives | 3~ 8 | 50 ~ 70 | 130 ~ 200 | 230 ~ 310 | 300 ~ 450 | 800 ~ 1000 | 800 ~ 1600 |

| Functional masterbatch | Degradable masterbatch: PE, PS, etc. + starch, etc. | 3~ 8 | 40 ~ 80 | 120 ~ 200 | 200 ~ 290 | 300 ~ 450 | 800 ~ 1000 | 800 ~ 1600 |

| Flame retardant masterbatch: PP, PA, ABS, PBT, etc. + flame retardant and other additives | 3~ 8 | 50 ~ 90 | 130 ~ 230 | 260 ~ 390 | 450 ~ 650 | 1000 ~ 1400 | 1300 ~ 2300 | |

| Double anti-master batch: PE + anti-fog dripping agent, stabilizer, etc. High heat preservation masterbatch; Cooling masterbatch; Rheological modified masterbatch | 3~ 8 | 50 ~ 70 | 90 ~ 130 | 230 ~ 310 | 350 ~ 450 | 800 ~ 1000 | 800 ~ 1600 | |

| Carbon black masterbatch: PE, EVA, ABS, etc. + carbon black | 3~ 8 | 30 ~ 50 | 80 ~ 130 | 200 ~ 290 | 300 ~ 450 | 700 ~ 900 | 800 ~ 1300 | |

| Reinforced modification of glass fiber (carbon fiber) | PP, PBT, ABS, AS, PA6, PA66, PC, POM, PPS, PET, etc. + long fiber or short fiber or whisker | 5~ 10 | 70 ~ 100 | 160 ~ 230 | 260 ~ 390 | 400 ~ 600 | 800 ~ 1200 | 1300 ~ 2100 |

| PP, PBT, ABS, AS, PA6, PA66, PC, POM, PPS, PET, etc. + carbon fiber | 5~ 10 | 40 ~ 80 | 130 ~ 210 | 230 ~ 390 | 300 ~ 450 | 800 ~ 1000 | 900 ~ 1800 | |

| Special materials | EVA hot melt adhesive, polyurethane | 3~ 8 | 40 ~ 80 | 80 ~ 120 | 130 ~ 200 | 250 ~ 300 | 600 ~ 700 | 600 ~ 1300 |

| Fluorine rubber | 3~ 8 | 30 ~ 50 | 50 ~ 100 | 130 ~ 200 | 200 ~ 250 | 500 ~ 650 | 600 ~ 1200 | |

| Cable coating material, acetate fiber, pp cigarette filter material | 3~ 8 | 40 ~ 80 | 130 ~ 200 | 260 ~ 330 | 400 ~ 500 | 1000 ~ 1300 | 1300 ~ 2100 | |

| TPR sole | 3~ 8 | 80 ~ 130 | 200 ~ 260 | 390 ~ 460 | 600 ~ 700 | 1200 ~ 1400 | 1300 ~ 2600 | |

| Luminescent plastics, antibacterial plastics, anti-ultraviolet plastics, PE crosslinkable pipe materials | 3~ 8 | 50 ~ 80 | 160 ~ 230 | 290 ~ 390 | 450 ~ 500 | 800 ~ 1000 | 900 ~ 1600 | |

| All kinds of cable materials | HDPE, LDPE, LLDPE, MDPE insulation material, sheath material; PE radiation crosslinked cable material; PE Silane Crosslinked Cable Compound | 3~ 8 | 40 ~ 80 | 130 ~ 200 | 230 ~ 330 | 400 ~ 500 | 650 ~ 900 | 900 ~ 1400 |

| Flame retardant polyolefin cable compound, PP cable compound | 3~ 8 | 80 ~ 100 | 160 ~ 230 | 330 ~ 390 | 500 ~ 600 | 1000 ~ 1200 | 1000 ~ 1600 | |

| Low Smoke and Low Halogen Flame Retardant PVC Cable Material | 5~ 10 | 30 ~ 50 | 100 ~ 160 | 200 ~ 260 | 300 ~ 450 | 700 ~ 850 | 800 ~ 1300 | |

| Reactive extrusion | Polyamide polycondensation, polyester melt polymerization, polyurethane addition polymerization, polycarbonate polycondensation, polyformaldehyde bulk continuous polymerization | 1~ 2 | 25 ~ 45 | 130 ~ 200 | 260 ~ 330 | 400 ~ 500 | 650 ~ 800 | 600 ~ 1300 |

| After treatment of exhaust devolatilization | Chlorinated polypropylene, superabsorbent resin, K-resin, chlorosulfonated polyethylene, fluororubber, etc | 1~ 2 | Max65 | Max130 | Max260 | Max400 | Max800 | Max1300 |

| Powder coating | Polyester type, epoxy type, propyl ester type, polyurethane type, acrylate type, etc. | 3~ 8 | 130-~ 200 | 260 ~ 390 | 520 ~ 650 | 900 ~ 1000 | 1800 ~ 2000 | 2000 ~ 4000 |

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China