Nanjing KY is one of the companies with the largest spare extruder parts storage in the whole industry, with more than 55000 varieties. With the first-class warehouse coding management system in the world, it can inquire about the real-time storage situation of spare extruder parts in a very short time to deal with various emergencies of customers. KY provides various twin screw extruder parts, including twin-screw extruder elements, screw shafts, barrels, and electrical components. Click and check our extruder components below.

Screw Element

Screw Element

1.All component materials are supplied by domestic first-line brands or European professional materials suppliers of twin-screw plastics machines.

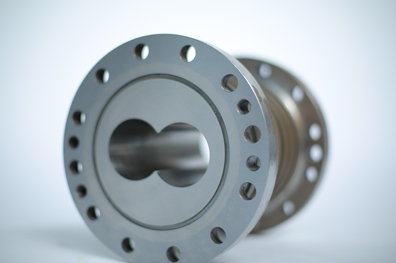

Screw Shafts

Screw Shafts

KY provides two standard spline mandrels, GB and DIN, to meet customer needs. The Machinable aspect ratio ranges from 28 to 68.

Barrels

Barrels

The shell of the basic grade cylinder is made of 45 # steel. The inner liner of the cylinder is made of basic alpha-101 bimetallic material.

Electrical components

Electrical components

KY can provide extruder spare parts of Siemens, ABB, ETON, Schneider, LS, IDEC, Yaskawa and other international and domestic brands.

KY has adopted the first-class brand constant temperature and humidity air conditioning device to ensure that twin screw extruder parts are not affected by temperature, humidity, and other external environments in the storage process.

With its own technical accumulation, KY machinery can also provide extruder spare parts for more than 40 kinds of twin-screw extruders of 7 International brands, including mechanical and electrical spare parts such as screw components, cylinders, and mandrels.

All extruder spare parts are guaranteed to be new, unused, and properly preserved. KY color masterbatch extruder components are made of imported materials, the best domestic materials, and first-class processing technology, and meet the quality, specifications, and performance requirements specified in the quality standards in all aspects.

Excellent materials and craftsmanship: Precision manufacturing processes and strict quality control processes ensure that every plastic extruder parts meets the highest standards, thereby reducing downtime and maintenance costs, and keeping your production line running efficiently.

Innovative design and technology: As a professional China plastic extruder machine factory, we continue to invest in research and development, using the latest technology and design concepts to optimize the performance of each plastic extruder parts. Our screw and barrel design can heat and melt plastic raw materials more efficiently, and the mold design ensures molding accuracy and consistency. These innovations not only improve production efficiency, but also significantly improve product quality

Professional service and support: We not only provide high-quality parts of extruder, but also provide customers with comprehensive technical support and after-sales service. Our team of experts is always ready to provide you with customized solutions to help you solve various challenges in production. Whether it is installation and commissioning, operation training, or troubleshooting, we can respond quickly

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China